- NDI division TOP

- Flaw Inspection

EddyInspector LXII - Eddy Current Flaw Detector for Production Lines

Eddy Current Flaw Detector for Production Lines

The EddyInspector LXⅡ is an eddy current flaw detector for production lines that offers full basic functionality and maximum cost-efficiency.

Focusing on ease of use and viewing, the detector is designed to be user-friendly, even for inexperienced operators.

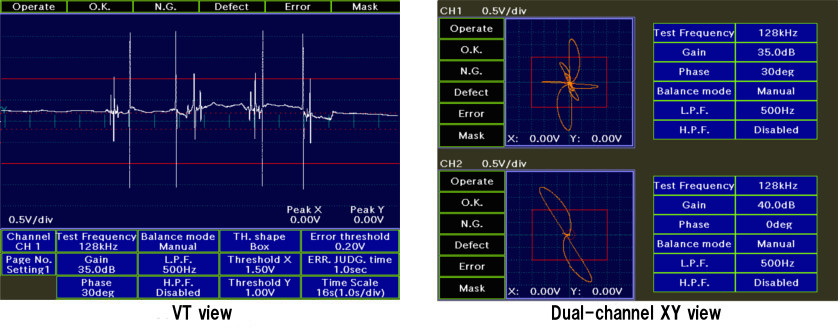

It offers new types of waveform view which old EddyInspector LX did not offer - VT view and dual-channel view - as standard.

It also offers optional functions for various inspection.

Improvements on the previous models

- ■Standard

-

Detection of workpiece rotation error.

VT waveform view.

Mask capability that can disable parts of inspection.

External inputs / outputs test.

Prohibition of setting parameters, which can be set for each parameter.

Screen lock.

Dual-channel views of XY and VT waveform for dual-channel model.

- ■Option

-

Storing up to 100 parameter setups, communication capability that can change parameter setups, and the included PC software which backups and restores parameter setups.

Threshold-2 in the shape of box, circle, corner, and ellipse.

Communication capability that can send a peak voltage.

Main Features

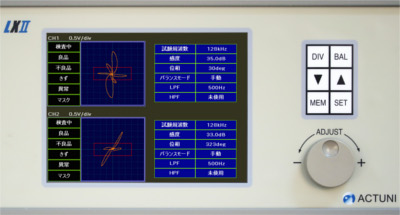

- A 6.5-inch TFT color LCD with six buttons and a jog dial for user-friendly operation

-

The EddyInspector LXⅡ has a TFT color LCD that is easy to read even in bright light. Despite being a digital display, it achieves analog-like smooth plotting. Also, taking advantage of its digital design, it offers a storage feature that can display waveform traces. The six buttons and jog dial allow the operator to perform all tasks intuitively, so even inexperienced operators can quickly master the use of the detector.

- Intuitive testing views

-

The EddyInspector LXⅡ offers new type of waveform view - VT view - making it easier to check the temporal change of the measured waveform. Dual-channel type EddyInapector LXⅡ offers also new dual-channel waveform views simultaneously - XY view and VT view - making it possible to check dual-channel inspection status simultaneously, though old model offers an only single-channel waveform view which can be switched to the other channel independently. The single-channel view is used to perform calibration, while the dual-channel view is used during inspection to check the inspection status of the individual channels on a single screen.

- Analog signal outputs

-

The EddyInspector LXⅡ has an analog output (BNC connector) for each of the x and y components of flaw detection signals so that the signals can be recorded by a recorder.

- A wealth of control inputs and outputs

-

For reliable inspection, the EddyInspector LXⅡ offers inputs and outputs for control.

It employs a detachable terminal block to simplify the connection.

- Single- and dual-channel types available

- You can choose a single- or dual-channel type to suit your needs.

Download the latest Adobe Acrobat Reader from https://www.adobe.com/.

Specifications

| Test Channel | One channel model or two channel model |

|---|---|

| Inspection Method | Electromagnetic induction method |

| Probe Type | Self-induction or mutual-induction |

| Method of Excitation | Single frequency testing 10 Vp-p sine wave |

| Test Frequency | 2, 4, 8, 16, 32, 64, 128, 256, 512 kHz 600 kHz - 2000 kHz (100 kHz steps) |

| Sensitivity | 0.0 dB - 80.0 dB (0.1 dB steps) |

| Phase | 0 deg - 359 deg (1 deg steps) |

| Bridge Balance | Manual balance(approx. 100 ms) Follow-up balance (2 speeds) The follow-up speed is adjustable between 0000 - 0FFF. |

| L.P.F. | 50 Hz - 1000 Hz (10 Hz steps) -24 dB/oct |

| H.P.F. | OFF, 1 Hz - 500 Hz (1 Hz steps) -24 dB/oct |

| Testing |

Window comparator around the origin. ±0.20 V - ±9.99 V or DISABLE(0.01 V steps; each X and Y) detection of parts rotation error |

| Display | 6.5 inch TFT color LCD Parameters, OPE, OK, NG, Error, ET signal view (single or multi XY / VT), I/O check, permission of setting and LOCK |

| Language | Japanese and English (option) |

| Analog outputs | X and Y signal DC ±10 V (BNC connector) |

| External control inputs | P(+12 - +24 V power supply) N(power GND)、AUTO、OPE、CLR、BAL、MASK(terminal block) |

| External control outputs | OK、NG、RDY、OPE、BAD、MARK、WDT(terminal block) |

| Environmental | Temperature range: 5 ℃ - 40 ℃, Humidity: 10 % - 85 % (without condensation) |

| Power | Single phase; AC100 - 240 V ±10 %, 50 / 60 Hz 40 VA |

| Dimensions | W: 370 mm H: 149 mm D: 350 mm(not including rubber legs and connecters.) |

Video

- Demo Video

-

This video demonstrates how the EddyInspector LXⅡ can be used to perform an nondestructive, noncontact inspection. This is a basic model in our range of eddy current flaw detector for production lines. It employs electromagnetic induction method and can inspect products with water or oil on them.