- NDI division TOP

- Nonconforming-Material Detector

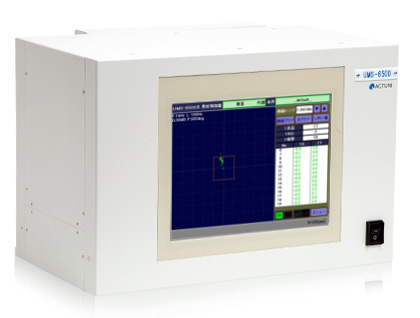

UMS-6500 II - Nonconforming-Material Detector for Production Lines

Nonconforming-Material Detector

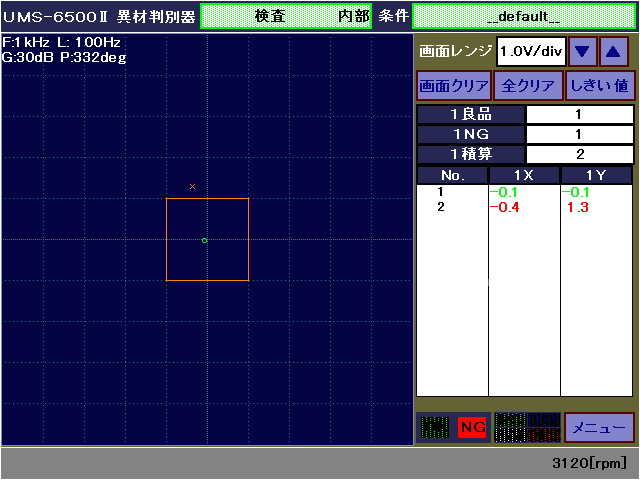

The UMS-6500II is a testing device for production lines that employs an electromagnetic induction method to inspect bearings, quenched workpieces, and other parts for nonconformity in terms of material, heat treatment, and shape.

The detector is designed to allow the operator to interactively set up all parameters on the touchscreen, so even inexperienced operators can easily use it. In addition, when in Auto mode, the detector offers an automatic evaluation feature that enables a high-speed inspection where the operator only needs to pass products through a test coil.

Main Features

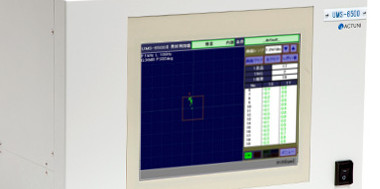

- A 10.4-inch TFT color LCD touchscreen

-

The UMS-6500II employs a TFT color LCD that is easy to read even in the dark. Also, the touchscreen provides intuitive operation.

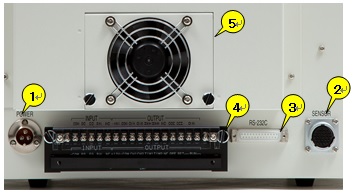

- Back panel

-

①Power socket

②Sensor connector

③RS-232C port

④I/O terminals (easily attachable/detachable)

⑤Cooling fan (replaceable)

- Simultaneous use of two types of test coils (only for dual-channel type)

- Two types of coils can be used to inspect two areas at once, or different inspection methods can be used simultaneously. Also, depending on what is being inspected, the UMS-6500II can detect nonconforming materials and check quenched hardness at the same time.

- A wealth of evaluation modes and I/O connectors that meet a wide range of on-site needs

-

For reliable inspection, the UMS-6500II includes a variety of inputs and outputs. These I/O connectors make it possible to set up a production line that prevents uninspected products from being released in the event of a power failure, faulty CPU, or misoperation.

To support a wide variety of production lines, the detector offers several inspection modes, including:

●Auto mode, for performing automatic inspections

●EG mode, for performing inspections using an external timing source

●PS mode, for performing inspections using a proximity sensor and internal delay timer

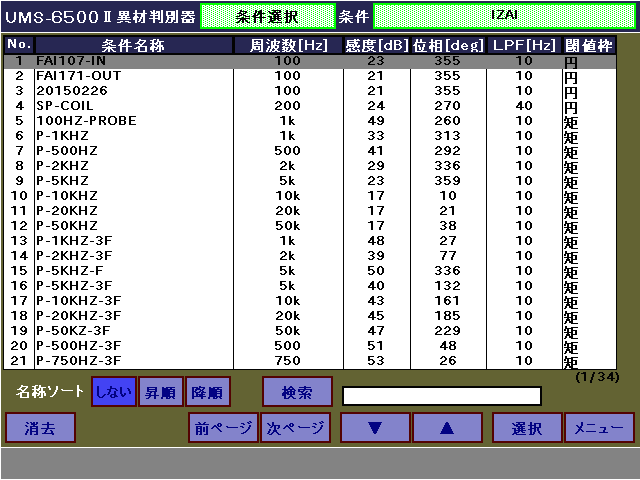

- Capable of registering up to 400 inspection parameter setups

-

The UMS-6500II can register up to 400 parameter setups used to inspect products.

Parameter setups can be named using alphanumeric characters and symbols.

Because parameter setups are listed, they are easy to select or delete.

The detector offers new features—sorting, text search, and page switching—making it easier to search for the desired inspection parameter setup.

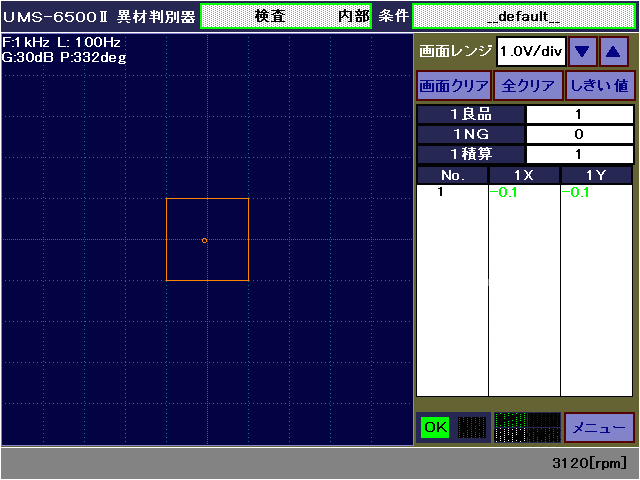

- Easy-to-understand evaluation zones

-

The UMS-6500II offers a square zone, which enables easy numerical control; an elliptical zone, which can handle specific variations; and an automatic setup mode that determines an evaluation zone from the standard deviation of several products.

- Password protection prevents inexperienced operators from accidentally changing advanced settings

-

The UMS-6500II is protected by a four-digit password configured to prevent its parameter settings (excluding some settings such as inspection parameter setups) from being accidentally changed.

Download the latest Adobe Acrobat Reader from https://www.adobe.com/.

Specifications

| Probe Type | CH1: Mutual-induction or self-induction CH2: Self-induction CH1 and CH2: DIF mode or ABS mode |

|---|---|

| Excitation Current | CH1: Single frequency 22 Vp-p (max) 1.0 Arms (max) CH2: Single frequency 6 Vp-p |

| Test Frequency | 20 Hz - 100 kHz (independently set for CH1 and CH2) |

| Sensitivity | 0 dB - 56 dB (1 dB steps) |

| Phase | 0 deg - 359 deg (1 deg steps) |

| L.P.F. | 10 Hz - 100 Hz (10 Hz steps) 100 Hz - 1000 Hz (100 Hz steps) ‐24 dB/oct |

| Bridge Balance | Electronic balance(subtraction offset for every balance) |

| Sampling cycle | 0.1 ms |

| Display | 10.4 inch TFT color LCD touchscreen |

| CPU | SH4(147 MHz) |

| Judgment Mode | PS mode, EG mode, PS+EG mode, Manual mode and Auto mode |

| Serial Port | RS-232C(9600 bps - 115200 bps) |

| External Control Inputs | PS, EG and BAL for photoelectric sensor, etc. |

| External Control Outputs | RESULT1, RESULT2, TIMING1, TIMING2, OPE, SET and RUN |

| Environmental | Temperature range: 5 ℃ - 40 ℃, Humidity: 10 % - 85 % (without condensation) |

| Dimensions | W: 402 H: 282 D: 288 mm (not including rubber legs and connecters.) |

| Weight | Approximately 11 kg |

| Power | AC 100 - 240 V ±10 %, 50 / 60 Hz |

| Electric Energy Consumption | 90 VA |

Video

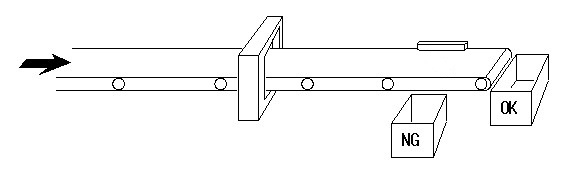

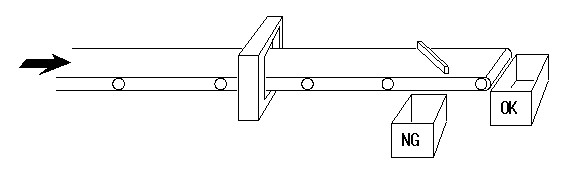

- Application example

-

Here is a simple animation of a UMS-6500II

detector being used on a production line.

Pass/fail results are output to a mechanism that

sorts products accordingly.