- NDI division TOP

- Maintenance Inspection

EddyStation MWIII - Windows-Based Eddy Current Flaw Detector

Windows-Based Eddy Current Flaw Detector

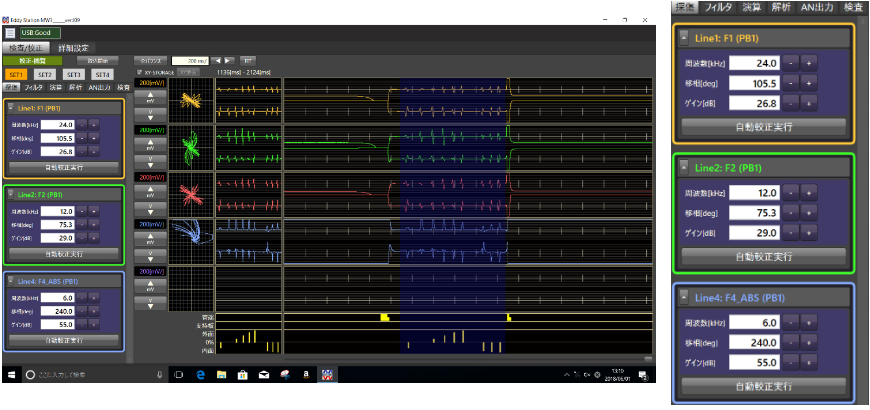

Developed based on our many years of experience, the EddyStation MWIII is the flagship model in our range of multi-frequency multi-channel eddy current flaw detectors for maintenance inspection. Operating the detector is as easy as using a mouse on a Windows PC, so even inexperienced operators can quickly master its use. The operater can use our dedicated software to display the values of the x- and y-axis amplitude voltages and phase angle of the stored waveform, and create data for reports.

Improvements on the previous models

-

The maximum number of available single frequency probes has been increased from three to four.

The maximum number of signals on the screen has been increased from four to five.

These allow us to customize to our customers requirements in more detail than ever before.

Main Features

- Four-independent-channel flaw detection capabilities and a dual-channel arithmetic circuit enable a wide variety of inspections

-

The EddyStation MWIII offers four-independent-channel excitation and detection circuits. It can be used as an one-channel three-frequency flaw detector or a four-independent-channel single-frequency flaw detector. The ET parameters: gain, phase, and filter, can be set for each channel or frequency.

- High-speed sampling

- The EddyStation MWIII can perform high-speed sampling up to 10 kHz (10,000 points per second) to plot up to five types of signal waveforms simultaneously. Inspection data is stored in PC memory and save into PC strage up to 400 seconds.

- Instant defect identification in real-time analysis

-

Once waveform data predetermined from artificial flaws is input, the EddyStation MWII can create wall thinning curves. Then, based on waveforms obtained during an inspection, the detector can analyze the types and depths of the defects and display the results in a chart.

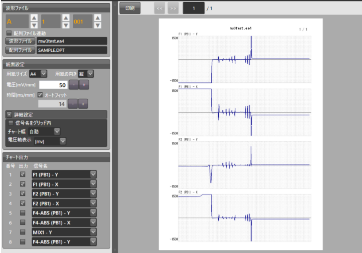

Test signals can be output to a commercially available chart recorder in real time. Some chart recorders can be set to automatically start operating at the start of an inspection. (This applies only to chart recorder models we have checked for compatibility.)

- Works perfectly with a bobbin coil designed to inspect heat exchanger tubes

- When an inspection is conducted based on tube row numbers, the EddyStation MWII detects tube ends, and then automatically performs phase analysis and records waveforms.

By using an optional remote pendant, the operator can start and end an inspection and check tube row numbers externally.

- Acquired waveforms can be used in other applications

-

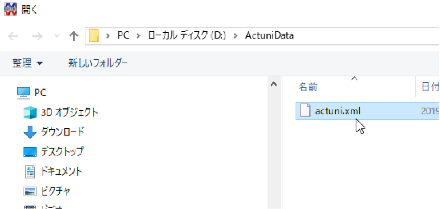

On a PC not connected to the detector, the dedicated software starts up in playback mode, allowing the operator to reanalyze waveforms acquired on-site, paste images into other applications, or perform other tasks in a flexible manner.

- Remote Pendant(Option)

-

The Remote Pendant is a device that can be operated remotely when the inspector inserting the probe and the eddy current detector are far apart, such as when working at heights. Operation buttons such as "Balance," "Start," and "Stop," and buttons for tagging when an internal probe cannot be inserted, such as "Plug," "Not inserted," "Foreign material," and "Uninspected," can be operated on the tablet. Since it is connected wirelessly to the PC on the eddy current detector, it does not interfere with inspection work.

Download the latest Adobe Acrobat Reader from https://www.adobe.com/.

Specifications

| Method of Excitation | Three frequencies electromagnetic induction method; self induction; differential or absolute method; independent single frequency for each of four channels. |

|---|---|

| Test Frequency | 500 Hz - 2 MHz(100 Hz steps) |

| Sensitivity | 0.0 dB - 80.0 dB(0.1 dB steps) |

| Phase | 0.0 deg - 359.9 deg(0.1 deg steps) |

| Bridge Balance | Electronic automatic balance or follow-up balance |

| L.P.F. | Independent adjustment for F1, F2 and F3; 50 - 1000 Hz(10 Hz steps)-24 dB/Oct |

| Analog Outputs | BNC connectors; X and Y signals for 4 cahnnels; ±10 V D/A sampling frequency: 10 kHz(resolution: 14 bit) |

| Scale | 0.1 V/DIV, 0.2 V/DIV, 0.5 V/DIV, 1,0 V/DIV and 2.0 V/DIV |

| Storage | Available to storage media which are supported by operating system. |

| Printer | Available to printers whitch are supported by operating system. |

| Operating System | Windows 10 or later |

| Recommended PC System Requirements | USB I/F port XGA(1024×768 dot)display rexolution |

| Environmental | Temperature range: 5 ℃ - 40 ℃, Humidity: 10 % - 85 % (without condensation) |

| Dimensions and Weight | H: 94.5 mm W: 370 mm D: 280 mm (not including rubber legs and connecters.), apploximately 4.5 kg(not including cables) |

| Power | AC 100 - 240 V ±10 %、50 / 60 Hz、approximately 40 VA |